How to keep the Ice Tech PS machine in good condition?

Last week we explained how to keep the ice machine Ice Tech SS in good condition. This week we are introducing the range of Ice Tech PS ice cubes.

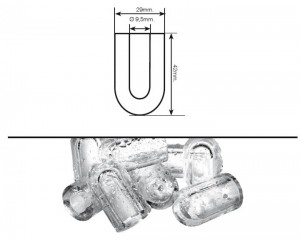

Ice Tech PS ice cubes are the best ones for both your drink and your icemaker machine! They are hollow cubes with a high volume and whose dimensions are similar to a finger. Thus, cooling is more efficient.

Ice Tech PS machine is equipped with a complete electromechanical control, without motors or injectors that work with a pump. This makes it extremely reliable when water quality is not good.

How to clean it?

As we always tell you, we recommend checking and cleaning Ice Tech machines every six months. It is extremely important to unplug the machine each time we clean it.

We are going to explain how to clean every part of the machine. If you have already learned to clean the Ice Tech SS machine, it will be a piece of cake 😉

-

Water condenser

In order to clean the Ice Tech machine water condenser we must disconnect the water inlet or close the tap and disconnect the water inlet and outlet of the condenser. Afterwards, we must prepare the magic formula, which is a 50% of phosphoric acid and distilled water. Once we have it, we will make it flow through the condenser.

-

Air condenser

In order to clean the Ice Tech machine air condenser we must repeat the first step of the water condenser, which is to disconnect the water inlet or close the tap. Once we have done that, we must clean the finned area with a vacuum with brush, a non-metallic broach or low-pressure air.

-

Cleaning Cuba stock

The first same steps: disconnect the machine and the water, empty the ice cubes stock and we can now use a kitchen cloth and soap. The machine should be well disinfected. If white lime stains do not disappear, we should rub them with lemon and then clean it with a cloth. Then you should thoroughly rinse it with water, dry it well and start again.

-

Input filter cleaning

The input filters often clog when the machine starts working, especially during the plumbing. We should simply drop the hose and clean them under running water.

-

Control of water leaks

We have to prevent water leaks in order to prevent breakages and flooding. Whenever we manipulate the machine, we must check all water connections and the state of the clamps and hoses.

Let’s do it!